Mechanical equipment 5 lubrication parts damage causes and solutions, with practical lubrication skills

The purpose of lubrication management is to prevent the lubrication failure of equipment, reduce the loss caused by overheating and shutdown of equipment, save maintenance costs and reduce the replacement of parts, prolong the service life of equipment, reduce the consumption of lubricants and save the cost of purchasing lubrication materials. Modern mechanical equipment is developing towards the direction of high precision, high efficiency, high speed, heavy load, small, maintenance-free and energy saving, thus putting forward higher requirements for friction parts in mechanical equipment.

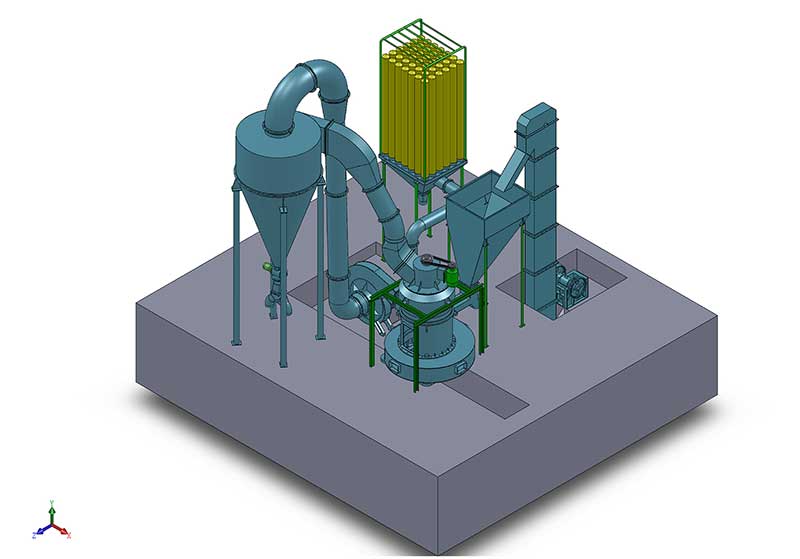

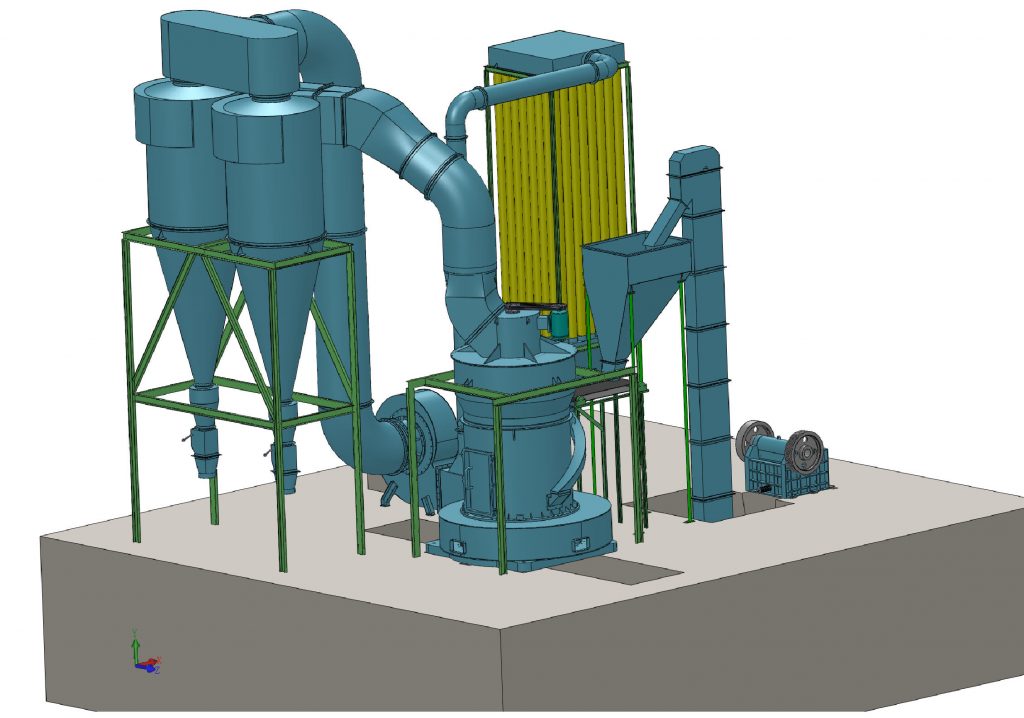

The mechanical structure, working principle and operation process of Raymond mill are introduced

Raymond mill is commonly used for grinding equipment, mainly used in barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, quartz, lime, active clay, activated carbon, bentonite, kaolin, cement, phosphate ore, gypsum, glass, insulation materials mohs hardness is not greater than 9.3, High fine powder processing for more than 280 kinds of materials in mineral, chemical and construction industries with humidity below 6%. Raymond mill is mainly composed of main engine, analysis machine, blower, cyclone separator, pipe device, motor and so on. The main machine consists of a frame, air inlet volute, shovel, grinding roller, grinding ring, cover shell and motor. Auxiliary equipment has jaw crusher, dustbowl hoist, electromagnetic vibration feeder, electric control cabinet, etc., users can choose flexibly according to the site situation.

The working principle and structure of Raymond mill are introduced

The working principle of This machine is composed of crusher, hoist, storage hopper, electromagnetic vibration feeder, blower, main engine, analysis machine, cyclone collector, pipeline system, dust hopper, electric control cabinet, etc. (see the following figure). Material of the crusher into less than 20 mm of material, after the hoist to storage hopper, again by electromagnetic […]

Summary of 15 kinds of faults, causes and countermeasures of bag filter

Under the current high pressure of environmental protection, many industries are facing severe tests, and enterprises also put environmental protection in an important position of enterprise development. Bag filter is an efficient dust removal equipment for air pollution control, which is widely used. Understand the common faults and solutions of bag filter, and can easily […]

Safe operating procedure for Ramon mills

1. Only those who read the manual and are familiar with the performance of the machine can operate the machine. 2, there is a strict shift system, the class should set up a record book, detailed record of the operation of the machine (including mechanical operation, lubrication, temperature rise, sealing, etc.), each shift output, quality, […]

Maintenance and troubleshooting of mill

1\When the new machine is put into operation, the loosening of connecting bolts should be checked frequently, especially the loosening of bolts of main machine and main machine roller grinding device. 2, roller, grinding ring, shovel knife and other wearing parts should be replaced in time after wear, replacement of roller, should be replaced at […]

Mill maintenance and troubleshooting, Raymond mill maintenance

1. When the new machine is put into operation, the loosening of the connecting bolts should be checked frequently, especially the loosening of the bolts of the main machine and the main machine roller grinding device. 2, roller, grinding ring, shovel knife and other wearing parts should be replaced in time after wear, replacement of […]

Preparation before starting the mill

1. Preparations before starting: (1) The following items must be checked before starting: Is the power supply voltage consistent with the requirements? It is not allowed to start when the voltage is lower than 360 VOLTS. Check whether the electrical circuit meets the requirements of the drawings. (2) Check whether the connecting bolts and fastening […]

Starting steps of Raymond mill

1. Preparation before startup: (1) The following items must be checked before startup: Whether the power supply voltage meets the requirements. If the voltage is lower than 360 V, it is not allowed to start up. Check whether the electrical circuit meets the drawing requirements. (2) Check whether the connecting bolts and fastening screws are […]

Detailed explanation of four devices of jaw crusher

The type crusher is mainly used for crushing large particle stones, granite, limestone and construction waste. It is widely used in many departments such as mining, smelting, building materials, highway, railway, water conservancy and chemical industry. It can crush all kinds of materials with compressive strength not exceeding 320 MPa. There are four major devices […]

[standards] 426 industrial standards such as air classifier, pulverizer, crusher and magnetic separator were approved

Recently, the Ministry of industry and information technology approved 426 industrial standards, including mineral vertical air flow classifier, countercurrent contact inflatable flotation column, pendulum mill, flexible graphite wire for braided filler and superconducting magnetic separator, including 249 in machinery industry, 42 in automobile industry, 10 in pharmaceutical equipment industry, 106 in […]