Raymond mill is commonly used for grinding equipment, mainly used in barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, quartz, lime, active clay, activated carbon, bentonite, kaolin, cement, phosphate ore, gypsum, glass, insulation materials mohs hardness is not greater than 9.3, High fine powder processing for more than 280 kinds of materials in mineral, chemical and construction industries with humidity below 6%.

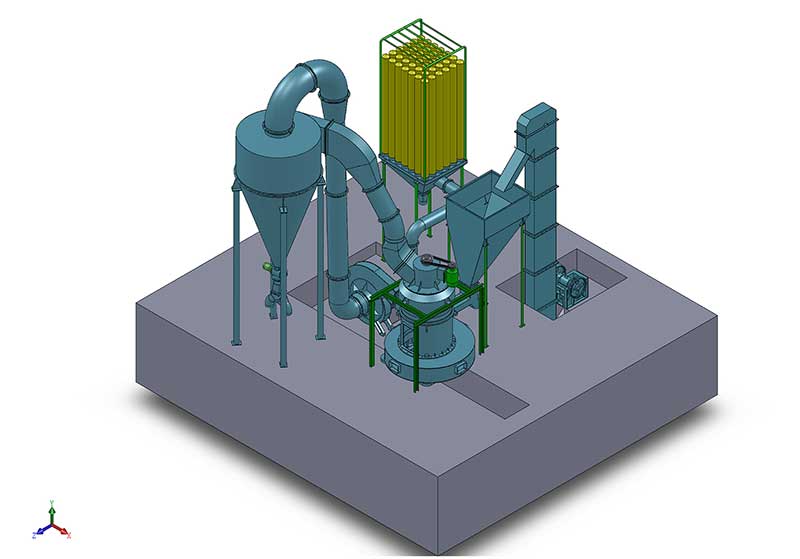

The mechanical structure of a Raymond mill

Raymond mill is mainly composed of main engine, analysis machine, blower, cyclone separator, pipe device, motor and so on. The main machine consists of a frame, air inlet volute, shovel, grinding roller, grinding ring, cover shell and motor. Auxiliary equipment has jaw crusher, dustbowl hoist, electromagnetic vibration feeder, electric control cabinet, etc., users can choose flexibly according to the site situation.

1, the machine is vertical structure, covers an area of small, systematic strong, from rough processing of raw materials to transport to powder and final packaging, can become an independent production system.

2. Compared with other grinding equipment, the screening rate is as high as 99%.

3, Raymond mill main machine transmission device adopts airtight gear box and pulley, smooth transmission, reliable operation.

4, Raymond mill important parts are made of high-quality castings and profiles, fine technology, rigorous process, to ensure the durability of the whole equipment.

5, the electrical system adopts centralized control, grinding workshop can basically realize unmanned operation, and maintenance.

How a Raymond mill works

Raymond mill to break big block of raw materials to the feeding granularity, the bucket elevator will be material to the storage bin, and then by the electromagnetic feeder to host grinding cavity, enter into the grinding chamber of material between grinding roller and grinding ring grinding, grinding after FenZi machine classification, from the analysis of fan airflow to achieve the requirements of the fineness of powder with airflow management send LiRu cyclone collector, For separation and collection, and then discharged through the discharge device is the finished product.

The working process of the host is central axis rotation, through to spread gear drive with the top of the shaft connected to the plum flower rack, the rack is equipped with roller the franco-prussian education form a swinging pivot, it not only around the center, at the same time grinding roll around the orbit of ring at the same time, the shovel with roller turn in the process of cast material shovel feeding between grinding roller and grinding ring, form the packing layer, The material layer is crushed by the centrifugal force (extrusion force) generated by the rotation of the grinding roller, thus achieving the purpose of pulverizing.

The analysis machine drives the blades on the turntable to rotate through the speed regulating motor and the secondary deceleration, forming the grading effect on the powder. The blade speed is adjusted according to the particle size of the finished powder. When if you want to get a finer particles, it is necessary to improve the speed of the blade, make contact with FenZi increase leaves, make the undesirable FenZi was a leaf into the outer wall away from the air and coarse particles due to the gravity into the grinding chamber for resharpening, qualified into mouth FenZi through leaves with the airflow to the big cyclone collector, air separation and FenZi were after, FenZi is collected, The big cyclone collector on the performance of the mill have very important role, when take powder flow into the collector is a high rotation speed, after waiting for air separation and FenZi, air separation and FenZi, airflow with taper inwards to the bottom of the cone body wall contraction (from air natural length) to form a spiral upward air cylinder, then FenZi is collected.

Due to the upward spinning air core in negative state, bottom sealing requirement is very high, so the collector outside air must be strictly separated, or be collected under FenZi will again take away by the core flow, it directly affects the output of the whole machine, so the bottom with a lock powder collector, its role is to the outside world is isolated from the negative pressure gas collector pressure gases, This is a very important part, such as not installed powder lock or powder lock tongue plate sealing is not strict will cause no powder or less powder, affecting the output of the whole machine.

The production capacity of Raymond mill is affected by important factors

1. Hardness of materials. The harder the material is, the more difficult it is to grind the powder, and the more serious the wear of the equipment. Ramon grinding speed is slow, of course, ramon grinding capacity is small.

2, the humidity of the material, that is, when the moisture content of the material is large, the material is easy to adhere in the Raymond mill, and it is easy to block in the process of conveying the material, resulting in the reduction of the capacity of the Raymond mill.

3, the fineness of the material after Raymond grinding, fineness requirements are high, that is, the finer the material out of Raymond grinding is required, the smaller the capacity of Raymond grinding.

4, the composition of the material, Raymond powder powder before the material containing more influence Raymond powder, because these fine powder is easy to adhere to affect the transmission. For fine powder content should be in advance of a sieve.

5. Viscosity of materials. That is, the greater the viscosity of the material, the easier it is to adhere.

6, Raymond mill Raymond grinding parts (hammer, jaw plate) wear resistance is better Raymond grinding capacity, if not wear resistance, will affect Raymond grinding capacity.

Operation process of Raymond mill

Before the Raymond mill starts, check whether all access doors are closed tightly, check whether the jaw clearance of the crusher meets the grain size of the feed, adjust the speed of the analysis machine to reach the grain size of the approximate finished product. Finally, turn it on in sequence.

1, start the dustbowl elevator; 2, start jaw crusher; 3. After the material is stored in the bin, start the analytical machine; 4. Start the blower (start at no load and load again after normal operation); 5. Start the main machine of Raymond mill, and immediately start the electromagnetic vibration feeder when starting the main machine. At this point Raymond mill grinding work is the beginning.

The operation sequence of Raymond mill is simple as follows: Start: elevator → crusher → analysis machine → fan → host machine → feeder. When Raymond mill is shut down, each machine should be closed in the following order:

1, first close the feeder to stop feeding;

2. Stop the host about one minute later.

3. Stop the blower after cleaning the residual powder;

4. Finally, close the analytical machine.

The order of Raymond mill shutdown is: feeder → host → blower → analysis machine. Note: after conveying material to silo for a certain amount, the hoist should stop lifting crusher first and then stop lifting again, which should be changed according to the current storage amount.

Ramon mill in normal work is not allowed to refueling, to ensure production safety, in any part of the mill abnormal noise, or sudden increase in load should be immediately shut down for inspection, troubleshooting, so as to avoid major accidents. The remaining material in the mill must be taken out when the machine is started again, otherwise the startup will be affected by excessive current when the machine is started.