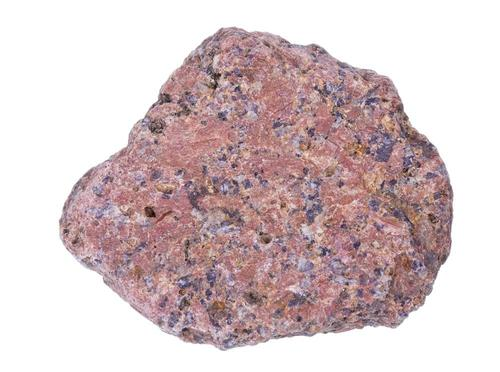

Granite is a kind of tectonic rock formed by volcanic lava rising to the surface of the earth’s crust under considerable pressure. The magma does not eject from the ground, but slowly cools and solidifies underground. It is a kind of plutonic acid igneous rock and belongs to magmatic rock (igneous rock). Granite is mainly composed of quartz, feldspar and mica. The content of feldspar is 40% ~ 60%, and the content of quartz is 20% ~ 40%. Its color depends on the type and quantity of components. The rock is hard and dense.

Granite is formed from igneous rock. It is a kind of hard steel crystalline stone. It is initially formed from feldspar and quartz and mixed with one or more black minerals. It is evenly arranged in structure.

Granite is mainly composed of quartz, feldspar and mica. The content of feldspar is 40% ~ 60%, and the content of quartz is 20% ~ 40%. Its color depends on the type and quantity of components. Granite is a rock with fully crystalline structure. High quality granite has fine and uniform grains, compact structure, large quartz content and bright feldspar luster.

Granite has high silica content and belongs to acid rock. Some granites contain trace radioactive elements, which should not be used indoors. Granite has compact structure, hard texture, good acid and alkali resistance and climate resistance, and can be used outdoors for a long time.

chemical property

Granite is mainly composed of feldspar, quartz and biotite, but also accompanied by the existence of other minerals. Various proportions are mainly as follows:

| component | SiO2 | Al2O3 | CaO | MgO | Fe2O3 |

content(%) | 67-76 | 12-17 | 0.1-2.7 | 0.5-1.6 | 0.2-0.9 |

Granite grinding process

Stage I: crushing

Large granite materials are crushed by the crusher to the feed fineness (less than 30mm) that can enter the pulverizer.

Stage 2: material grinding

The crushed small granite materials are sent to the raw material warehouse by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the vibrating feeder for grinding. After grinding, the milled materials are graded by the analyzer. Those whose fineness meets the specification flow into the large cyclone collector with the wind, and then discharged into finished products through the discharge valve. Those whose fineness is unqualified cannot be screened by the analyzer, but still fall back to the host for re grinding.

Stage III: storage or packaging of finished products in cans

① The finished products discharged from the discharge valve are transported to the finished product tank for storage by pneumatic conveying equipment.

② The finished products discharged from the discharge valve are packaged by a double mouth packaging machine.

③ The finished products discharged from the discharge valve are packaged by the ton baler.