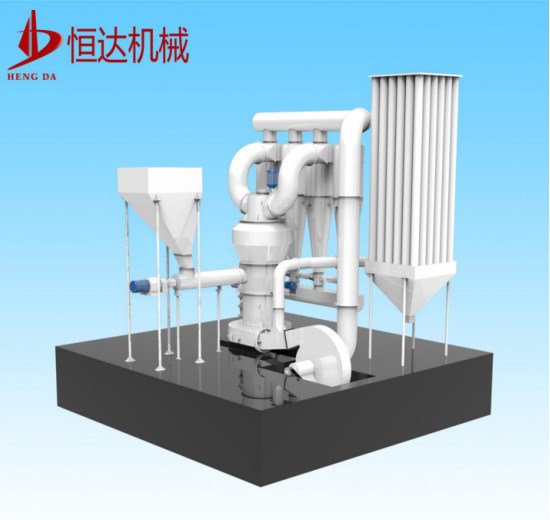

A new measure to improve oil leakage of vertical grinding roller

1 existing problems Oil leakage of grinding roller often occurs in cement plants with vertical mill, which is a difficult problem that always puzzles vertical mill manufacturers. Oil leakage not only pollutes the environment, but also increases the production cost. There are many causes for oil leakage of vertical grinding roller, which can be summarized as follows: First, the reason of grinding roller sealing. At present, the vertical grinding roller seal mainly adopts three skeleton lip seals, one dust-proof and two oil-proof. However, the working environment of the vertical mill is very bad, which belongs to the working condition of